mmGPS Milling

Achieve Predictably Smooth Roads Every Time With 3D Milling

Revision How You Do Road Resurfacing With a 3D Milling System

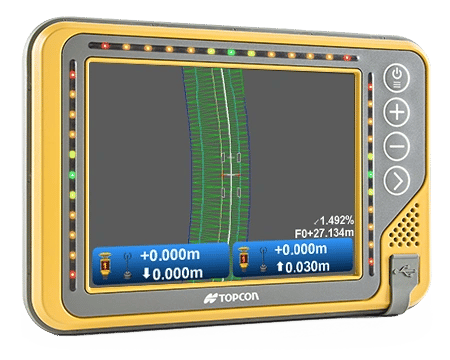

The 3D-MC Milling system by GPS Alaska combines the power of Topcon’s millimeter technology with 3D design to provide you with a fully automated milling system. Using 3D models, mmGPS Milling allows you to control milling depth with the touch of a button. Leave mill-marks in the past and discover the new, better way to resurface roads.

Achieve Predictable Results With mmGPS Technology

The 3D-MC Milling system removes all guesswork. This accurate positioning system combines GPS positioning with Lazer Zone ™ technology to provide the capabilities of GPS with the accuracy of a robotic total station. Your milling crew can predict and achieve the best possible results every time.

Key Features of mmGPS Milling

- 3D design milling

- Millimeter level accuracy

- Horizontal, vertical, or combined milling

- Multiple user capabilities in the same zone

- 2400-meter horizontal working range

- 40-meter vertical working range

- LaserZone™ laser reference technology

- No physical reference or mill-marks needed

Mill to Perfection With GPS Alaska

How much time, money, and effort could you save by milling within millimeter accuracy — without needing to add physical markers or leave the cab of your milling machine. The mmGPS milling system allows you to unlock your crew’s productivity and get accurate results every time. Prevent rework and boost profits with the top milling tech from GPS Alaska.