Do you still rely on the expertise of your operators to accurately control your earthwork machinery by eye? Do you still need at least two workers every time you need to check grade? What would happen if your most skilled operators quit or retired — are you confident you could find a replacement?

Modern machine control systems have become a vital upgrade for many construction companies. You likely have experienced first-hand the impact a shortage of skilled construction workers can have on your profitability, and you know how costly and time-consuming errors can be when grading or excavating. Upgrading your fleet with modern 3D machine control systems could help fill in this gap, making all of your operators —including the most inexperienced workers— more precise, efficient, and profitable.

With 3D machine control systems, a single operator can automatically check grade and position their machinery from the cab of their machine, without ever needing to leave the driver’s seat or relying on someone else hazardously checking grade from the ground.

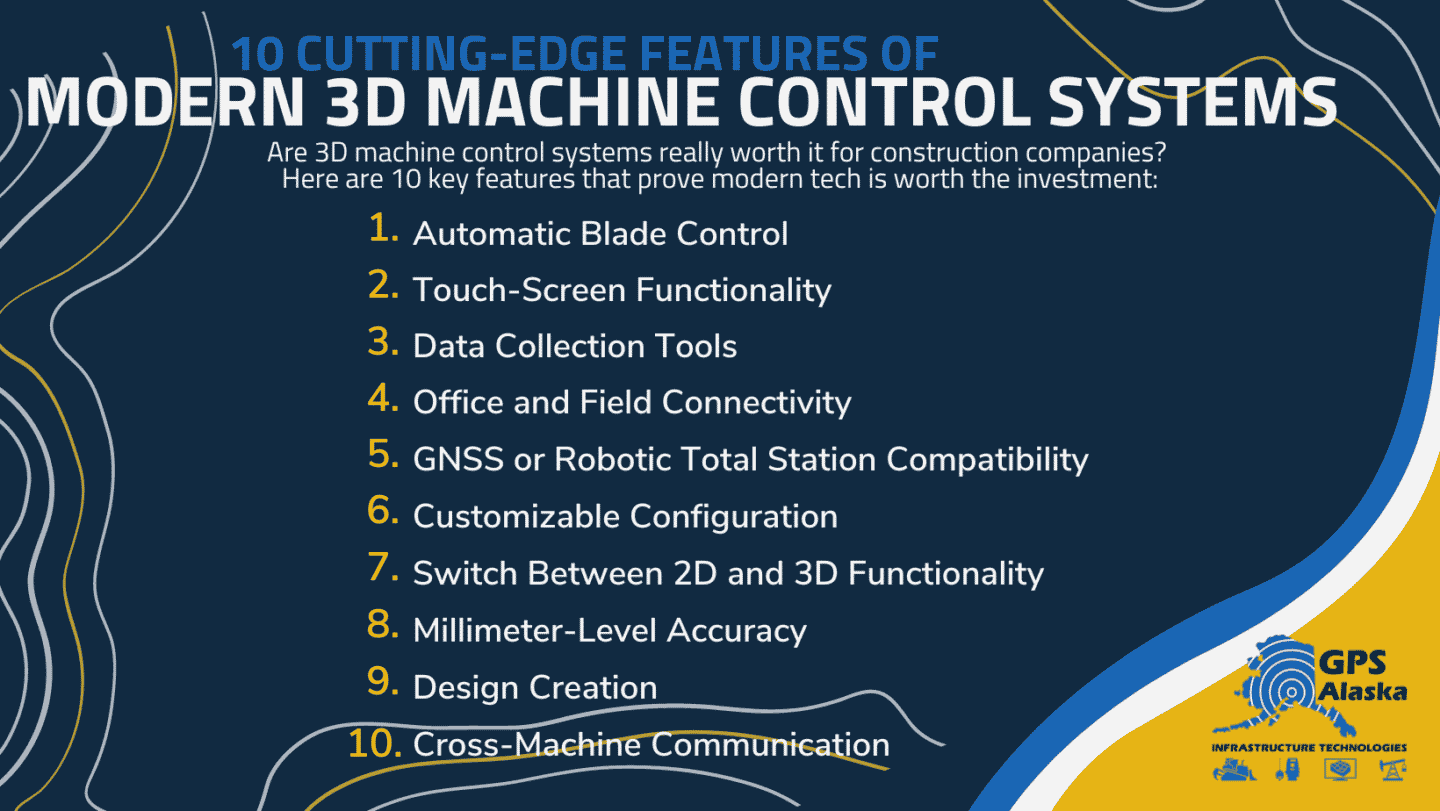

Machine control systems have been around for a couple of decades. However, the technology of today far surpasses the basic laser and sensor systems of the past. Here are ten key features of 3D machine control systems that prove this modern technology is worth the investment.

Want to explore your options for modern machine control systems? Speak with an expert at GPS Alaska today.

1. Automatic Blade Control

The most fundamental function of 3D machine control systems is to automatically grade, drill, etc. at the right location and level. It also eliminates the need for manual staking. Using positioning information, often gathered from GNSS signals or total station, and a 3D model of the site, your machine will digital stake out the project and know exactly how to position the cutting edge of the blade.

2. Touch-Screen Functionality

Some modern machine control systems have taken the form of familiar devices, like tablets and mobile phones. They use intuitive interfaces that are familiar to operators of any skill level and can be easily controlled with the swipe of a finger.

3. Data Collection Tools

Data is a valuable tool for construction workers, especially from a project management view. With real-time data on the performance of your crew, you can determine if you’re on track for meeting deadlines

and make adjustments as needed to improve the productivity of your team. Data can reveal hiccups in your workflow and allow you to better track the profitability of your operation. Additionally, you can more easily detect if an error has occurred and find solutions on the spot.

4. Office and Field Connectivity

Communication between your crew and office is a key piece of your overall productivity. If you consistently struggle to get your team on the field and your team in the office on the same page, you’re bound to run into delays, conflict, and errors. With the right construction software that uses the cloud, you can bridge the gap and allow operators in the cab and remote office teams to access the same data in real-time.

5. GNSS or Robotic Total Station Compatibility

Technology like the MC-Max Dozer from Topcon allows operators to easily switch between positioning software depending on the project at hand. If you have open access to the sky, you can use GNSS to bring your highly accurate positioning data. If you are in a covered area where GNSS signals are weak, you can quickly switch modes and use your robotic total station.

6. Customizable Configuration

Modern machine control systems can be tailored to your specific business needs and the current project. Whether you need something more simple or more complex, the interface and function of your system can be configured to your specific requirements.

7. Switch Between 2D and 3D Functionality

Can’t choose between 2D vs. 3D machine control systems? Well, how about both? Systems like the MC-X allow you to switch between “guidance” and “automatic” modes (or 2D and 3D modes). This means if you have a simple project and would rather not deal with creating a model, you can use the simpler guidance mode. However, when you need to grade as precisely as possible, you can choose to work in automatic mode.

8. Millimeter-Level Accuracy

Wondering just how accurate machine control systems are? Many of Topcon’s machine control products offer “millimeter-level accuracy,” which means your machine won’t ever grade, dig, or pave past one millimeter of your target while still moving at an efficient pace.

9. Design Creation

Many 3D machine control systems allow you to upload and view your model to the device reference. Some also allow you to create designs from the cab. From here, you can often share files with an office or remote team.

10. Communication With Other Machines

Machine control systems can synch with other machines in your fleet, enabling teamwork and collaboration when needed. For instance, the C-53 Intelligent Compaction allows you to see your own passes and passes made by other machines, allowing your team to work as quickly and accurately as possible.

How To Get Started With Machine Control Systems

As machine control systems continue to become more advanced and effective, construction companies will need to upgrade their fleet to compete. Those who have access to 3D machine control will be able to better meet their customers’ needs, completing projects with incredible accuracy and speed.

Machine control isn’t just for large construction companies either. Many smaller contracting businesses are investing in machine control systems to get an edge on the competition and to grow and scale their operation.

The question is no longer if you should invest in machine control but when. As the skilled workforce availability continues to dwindle and fresh talent becomes trained and familiar with machine control technology, you’ll struggle to keep up with the demand without upgrading.

So, how can you get started? If you’re unfamiliar with machine control systems, it can be difficult to know where to begin. The first step is calling your local construction technology provider. They can guide you through your options and help you decide what technology will likely provide the most ROI for your business.

Upgrade Your Alaskan Construction Fleet With GPS Alaska

GPS Alaska is the premier machine control provider in the state of Alaska. When you choose us, we’ll get you set up with everything you need including:

- · Machine control systems for your entire construction operation from top brands like Topcon

- · Purchase, rental, rent-to-own, and financing options that work with your budget

- · Surveying software and positioning products, like top-of-line GNSS receivers or total stations

- · 3D model building services so you can outsource all your modeling needs

- · Installation, crew training, remote support, and local maintenance when you need it

Not sure if a 2D or 3D system will best fit your needs? Want to know if your equipment is machine control ready? We’re happy to provide our expert guidance and walk you through everything you need to know to make an educated decision about purchasing machine control systems.

Want to keep up with the competition and watch your profits grow? Call GPS Alaska and upgrade your fleet with the most cutting-edge machine control systems available