Construction companies that utilize 3D machine control technology need a model of the worksite to properly automate and guide earthmoving equipment, such as graders, bulldozers, or excavators. These models can include digital terrain models (DTMs) and triangular irregular networks (TIN), which are often created using data gathered from surveyors on foot or through technology like drones.

Models play an essential role in modern machine control systems; however, having a plan to make these 3D models made can pose a challenge for many construction companies. As your modeling needs grow, you may wonder if it’s a good option to build your own models for machine control or to rely on a third party for your modeling needs. Here’s our guide on how to weigh the options.

Looking for an Alaskan company to take on your take-off and modeling needs? Call GPS Alaska to learn more.

How To Obtain 3D Models for Machine Control

Almost every project you tackle with a modern machine control system will require a model to be made. Except for very simple projects, like creating a basic road or pad, machine automation relies on access to a 3D model of the worksite. Construction companies are often faced with two options for having a terrain model made: They can either create a model in-house or outsource these services to a third-party provider.

In-House 3D-Modeling

Some construction companies find solutions for meeting their modeling needs within the company. There may already be someone on staff with the right skillset to draft in a CAD program, or the company will choose to train or hire someone to perform this function.

Doing your own modeling can be an excellent choice if you have access to a long-term employee who has the skill set necessary to create 3D models. However, you may overpay for modeling services if you hire someone dedicated to making DTM when your modeling needs are small. You also run the risk of wasting time and money spent on training an employee to do 3D modeling only for them to quit and leave for another company.

Additionally, if you’re unhappy with the quality of the models made, it can be complicated to find a model builder. If you’ve already invested in training someone on your staff, it can hurt your profitability to hire someone new. However, mistakes made by an inexperienced model builder can hurt the accuracy of your project, extending project times and cutting your profits.

Contractors also need to invest in 3D machine control automation tools and software for their model builder to use. You’ll need software to import and prepare data. You’ll also need to invest in a high-performance CAD workstation and software like Topcon’s Magnet Construction.

3D Modeling Services

The second option contractors have is to partner with a company that offers modeling services. As the construction industry is continuing to trend toward machine automation, there has been growth in the number of companies offering 3D modeling services for machine control. Many construction companies have taken advantage of these services and choose to outsource their modeling needs to a third party.

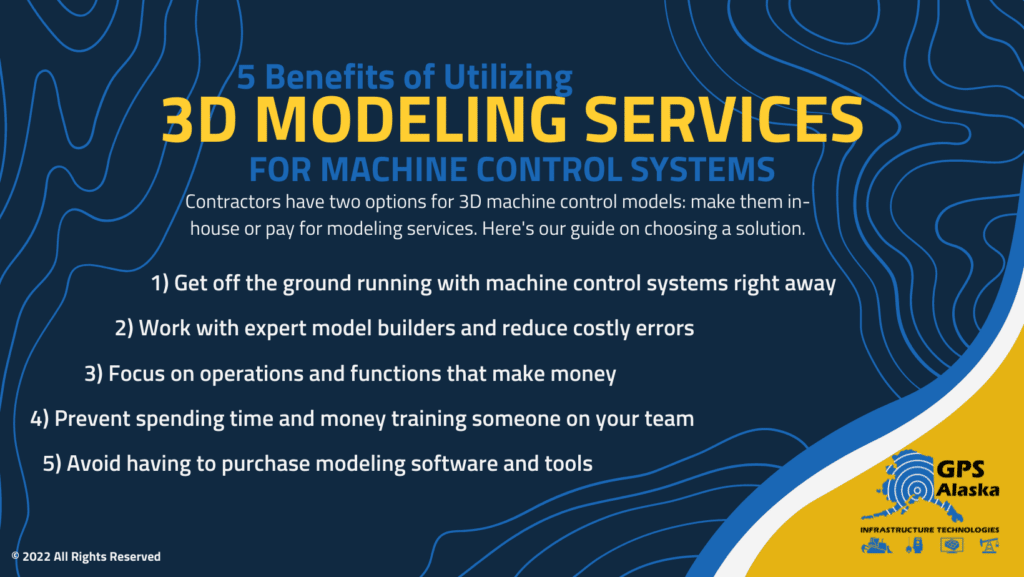

Outsourcing 3D models to a company offers many advantages to contractors:

- You won’t need to invest in training someone

- You can get off the ground running with your machine control systems right away.

- You can pay for modeling services as you need them

- Your construction team can focus on projects that make money

- You can rely on expert model builders – reducing the likelihood of error

- You can quickly end services if unhappy with the models and find a new company to partner with

- You don’t need to purchase modeling software or hardware.

While 3D modeling from an expert team comes with a high price tag, many companies find that outsourcing modeling services is an affordable option.

Should You Do Your Own Modeling or Outsource?

Should you build your models for machine control and checking grades? That depends on the size of your company and your employees’ skillset. If you’re running a smaller construction company and have someone on your team with experience in CAD and model building, you can potentially save money by keeping these services in-house. However, you’ll need to factor in overhead costs, such as the time and money required to adequately train the employee, potentially increase their salary, and create the models.

If you are trying to grow your construction business, modeling services allow you to more comfortable scale your operations. Since outsourcing your modeling services won’t require you to take on any regular costs, such as increased payroll, you’ll only pay for what you need. As your modeling needs grow, you can more easily predict the cost involved in outsourcing those models and be restricted by the capacity of your team.

The Future of Modeling Services for Machine Control

Machine control and advanced technology are the future of construction. The construction and surveying industries aren’t slowing down any time soon, and contractors depend on highly accurate, efficient technology to keep up with the growing demand and increase their profitability.

History shows us that these industries will continue to automate through technology. With time, tasks like model building and construction takeoff will fully commoditize, and construction companies will no longer build their own models.

How To Choose a Machine Control Model Company

If outsourcing model building, you need to partner with a machine control modeling company that has the right expertise. Here are a few factors to consider:

- Location: Partnering with a local business streamlines the process. You’ll never have to wait for an engineer or technician to travel to your location, allowing you to efficiently and consistently have models made as you need them. And you can actually work and meet with the staff doing your modeling, as opposed to working with a virtual team.

- Expertise: Not all models are created equal. Inexperienced or unthorough modeling companies may deliver a final product that has errors or is minimal. A good 3D machine control model should be free of data errors and comprehensive.

- Affordability: While not the main factor to consider, you will want to compare the costs of different modeling companies. You’ll need to consider your budget for modeling services and choose a model builder you can afford in the long term.

- Service: Choose a 3D machine control modeling company with a staff that you enjoy working with. You want to partner with a company that is responsive and can quickly deliver on your needs.

Partner With GPS Alaska for Your 3D Machine Control Modeling Services

GPS Alaska has a proven history of providing Alaskan contractors with the most reliable, accurate, and industry-leading products in the state. As your certified Topcon dealer and infrastructure technology provider, we can also provide 3D machine control modeling and take-off services so you can focus on scaling your business and getting the most out of the machine control systems you purchase.

And we are proud to offer our customers the highest level of service possible. When you choose GPS Alaska for machine control modeling services in Alaska, we go the extra mile to make sure you’re taken care of as quickly as possible.

Searching for expert modeling services? Contact GPS Alaska for more information.