The construction industry requires precise measurements and extremely accurate work. However humans are imperfect, and the reality is that rework happens more than you’d probably like to admit. When you complete work only to have to re-do it again, the impacts can be devastating for your pocketbook, your crew’s morale, your client relationship, and your company reputation.

The cost of construction rework is stunning. Many experts find that rework can cost between 5% to 30% of a project contract, or in some cases much more when all direct and indirect costs are considered. Clearly, if you’re looking for opportunities to increase profitability for your operation and cut down on unnecessary costs, minimizing rework is the first place to start.

While many would argue that some level of rework is inevitable for every construction project, there are many things you can do to do more work more accurately the first time around. By understanding why rework is happening in the place and employing the right tools to help you improve your accuracy and efficiency, you can greatly minimize the cost of rework and overcome the hurdle of constantly being bogged down by poor efficiency and accuracy.

Looking for tools that will help you prevent construction rework? Call our experts at GPS Alaska to discover technology that will increase your accuracy and speed.

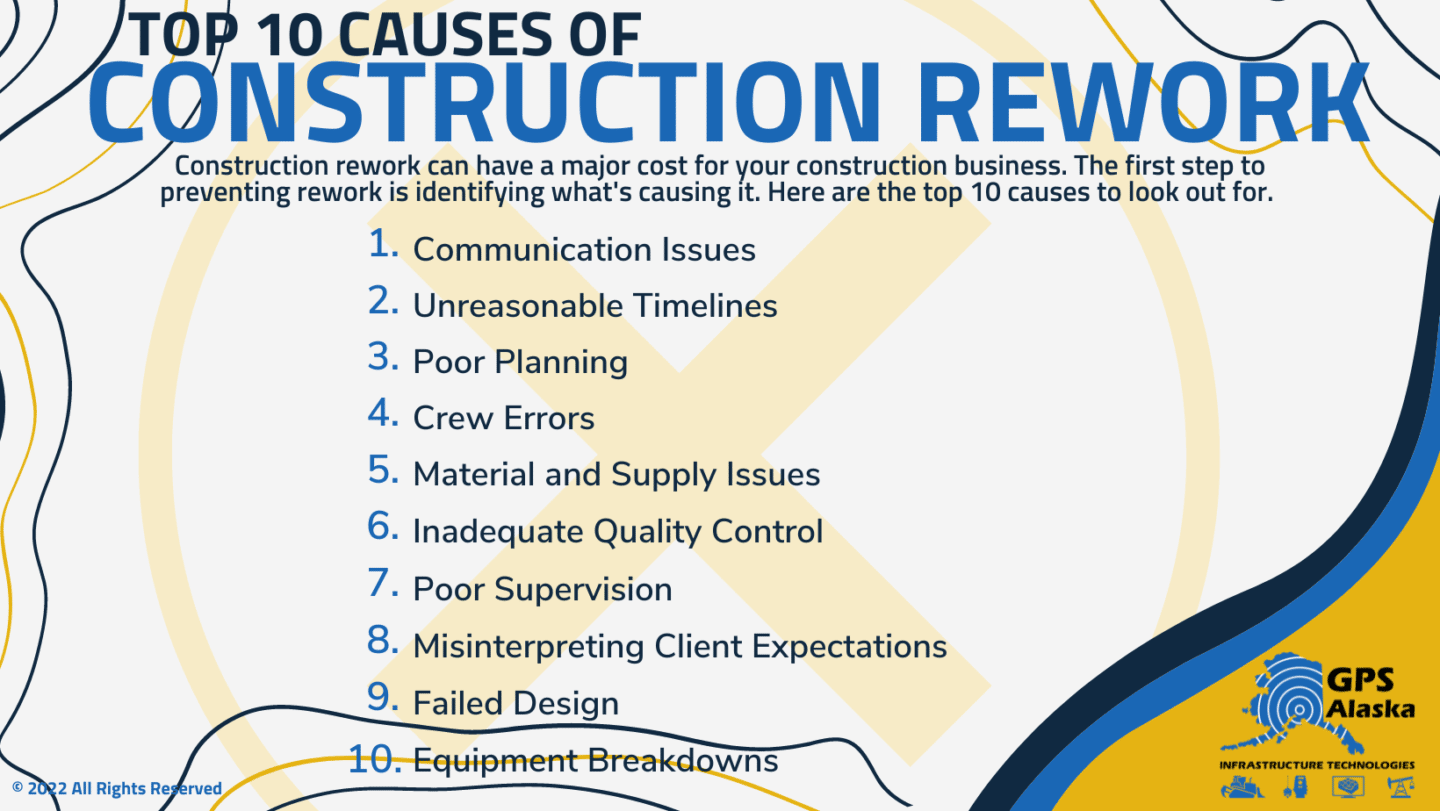

The Top Ten Causes of Construction Rework

The first step to preventing rework is identifying what’s causing it. These can be internal factors, such as those caused by a sticky process or poor craftsmanship, or external factors, such as weather or digital interference. Here are ten common causes of construction rework:

- Communication Issues: If your team struggles to communicate and collaborate smoothly, errors are more likely to happen. If there has been a change in plans or new data that has been collected, your team needs quick and easy access to this information to pivot or do their work accurately.

- Unreasonable Timelines: Tight deadlines almost always results in a fatigued and stressed crew that is more likely to make mistakes or cut corners. If you consistently take on projects with an unrealistic deadline or scope, you might be more likely to run into rework, which will only hurt your ability to make that timeline.

- Poor Planning: How many times have you started a project only to have to make major changes to the plan mid-way through the project? By properly lining out and documenting plans for the project ahead of time, you’re less likely to have to make changes and can detect potential causes of rework before they happen.

- Crew Errors: Sometimes your crew members are going to err. Inexperienced or poorly trained crew are the most likely to make a mistake, but even your most skilled, veteran team members are bound to cause errors at some point.

- Material and Supply Issues: Being undersupplied, ordering subpar materials, or buying the wrong materials can all lead to rework down the road. If you get to the end of the project only to realize the materials you purchased don’t meet the requirements of the job, this can require a lot of time and labor to fix.

- Inadequate Quality Control: Your quality control processes can go a long way in catching errors before they cost even more time and money to fix. Ensure you have processes in place to periodically and thoroughly ensure the work being done is accurate and well done.

- Poor Supervision: A great supervisor can set a high standard for their crew. Additionally, an experienced supervisor can help correct poor workmanship, catch errors, and find solutions to issues that present themselves. Even if you have full trust and confidence in your team, poor supervision leaves it up to your crew to make critical decisions on their own.

- Misinterpretation of Client Expectations: Not every client has an extensive understanding of the project at hand, and you can misinterpret a client’s expectations or vision. If your work doesn’t meet their requirements, this could require you to make changes.

- Failed Design: Even if your crew follows the plans to a tee and doesn’t make a single error, an inaccurate design has set them up for failure from the start. Poor data or model-making skills can put your crew in this unfortunate predicament

- Equipment Breakdowns: If your equipment fails on the job, this causes you to delay work and potentially damage work you’ve already done – leading to costly downtime, repairs, and rework.

How To Prevent Rework in Construction

Once you’ve identified some of the most common causes of errors for your crew, you can then implement strategies to prevent rework in future projects. Some causes of rework will cause you to take a hard look at your processes, including how you plan for construction projects, where you purchase products, how you manage your team, and how you communicate with clients.

It might be easy to simply tell yourself “We’ll do better next time” and simply push your crew to try and perform better on the next project. However, without making a major change to how you work, the likelihood is you’ll consistently run into the same issues.

While it’s vital you address any issues with training your crew or the management of your company, you should also consider the many tools available to help your entire time – both on the field and in the office – perform as accurately and efficiently as possible.

Machine Control Systems

If you’re running an earthmoving or paving operation, 3D machine control systems will completely evolve your construction operation. By harnessing the power of extremely advanced technology, you’ll no longer be dependent on the skill and accuracy of individual crew members. Rather, the system will ensure that the blade of your machine moves at the perfect angle and stops at just the right point.

Field-Office Software

If you struggle with communication, field-office software might be the missing piece you’ve been searching for. This type of software is designed to ensure there are no holdups in communicating between your office, management, and field teams. Construction cloud software also plays a major role in this, allowing your team to access and edit real-time data.

Modern Surveying Equipment

Outdated modes of surveying are more likely to result in data errors, which will result in an inaccurate site and project design. Modern surveying technology, like drones, GNSS receivers, robotic total stations, and advanced surveying software allow you to make more accurate and easy-to-follow designs.

Layout and Verification Technology

In building construction, digital layouts make your crew increasingly precise. By ditching paper plans and choosing a digital layout and construction verification workflow, you can rely on modern 3D positioning technology to create precise 3D layouts.

Investing in Solutions to Prevent Construction Rework

Construction technology can a big investment for your company. However, understanding how much construction rework costs you makes it easy to see the potential this hardware and software has to make you more profitable in the long run. Rather than waste dollars on redoing the same project over again, you can invest money into tools with a proven ROI that will make you more money, earn you more projects, and enable you to grow at a faster pace.

Ready to enter the next phase of growth for your construction company? Contact GPS Alaska to learn about our technological solutions.